Strengthen hydraulic safety and compliance with accumulator safety blocks and pre-charge verification from Mobile Hydraulic Specialties in Melbourne.

Accumulator safety blocks are essential components in hydraulic systems, designed to isolate and safely depressurise accumulators during inspection and maintenance. At Mobile Hydraulic Specialties, we emphasise the importance of pre-charge verification to keep hydraulic equipment reliable, efficient, and safe to operate. These practices also support alignment with AS/NZS 1200 compliance, the standard governing pressure equipment in Australia.

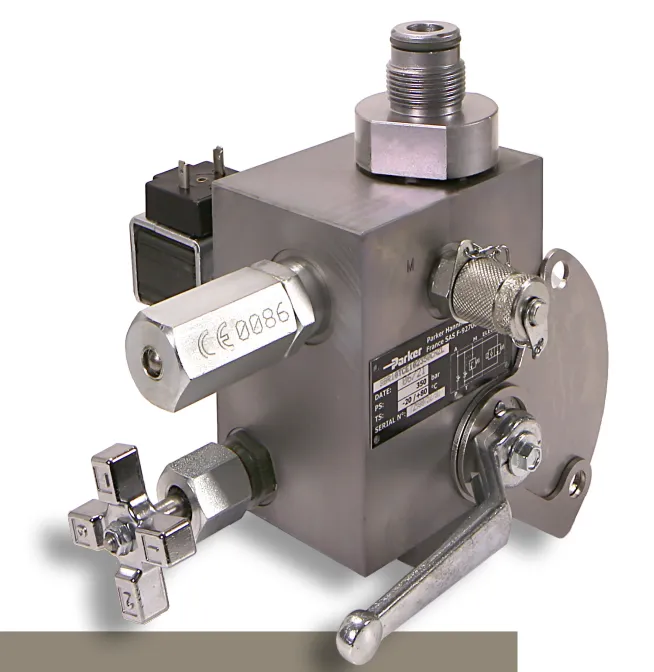

Accumulator safety blocks are designed to centralise the control of hydraulic accumulators, making systems safer and easier to manage. Their functions include isolating the accumulator from the system, safely depressurising it for maintenance, and providing integrated relief against overpressure. These features significantly reduce risks during servicing and day-to-day operation.

By incorporating safety blocks, operators add an important layer of protection to their hydraulic systems. While some smaller systems may operate without them, compliance-driven industries increasingly adopt safety blocks as a standard practice. This shift reflects their role in meeting regulatory requirements and enhancing workplace safety.

Pre-charge refers to the nitrogen gas pressure held within an accumulator’s bladder or piston, and it must be maintained within precise limits. Too little pre-charge reduces system efficiency and shortens accumulator life, while too much can damage valves and create unsafe operating conditions. Regular pre-charge verification ensures that the equipment performs as intended without compromising safety.

The process of verifying pre-charge is straightforward but must be carried out by trained personnel using proper gauges and procedures. It typically requires minimal downtime, making it a cost-effective maintenance step for critical hydraulic systems. For businesses, consistent pre-charge checks prevent costly failures and support the longevity of hydraulic components.

AS/NZS 1200 outlines requirements for pressure equipment in Australia and New Zealand. While the standard applies broadly, hydraulic accumulators fall within its scope. Businesses looking to align with these requirements should consider:

1. Installation Safety – Ensuring accumulators are fitted with the right safety devices, like relief valves or safety blocks.

2. Routine Inspections – Documenting and scheduling checks for accumulator performance and pre-charge pressure.

3. Maintenance Records – Keeping detailed logs of all servicing and verification activities.

4. Qualified Personnel – Engaging experienced technicians for installation and maintenance to support compliance.

Although compliance certification must be completed by authorised inspectors, these proactive steps help businesses operate in line with the standard’s intent.

Beyond regulatory alignment, incorporating accumulator safety blocks and regular pre-charge verification provides practical value:

• Enhanced workplace safety measures

• Reduced downtime and operational interruptions

• Extended service life of hydraulic components

• Improved efficiency and system reliability

• Increased confidence in regulatory compliance

For industries relying heavily on hydraulics, such as mining, construction, and manufacturing, these measures represent a balance between operational efficiency and safety obligations.

Accumulator safety blocks and pre-charge verification are essential practices for businesses seeking both safe operations and alignment with AS/NZS 1200 compliance requirements. While compliance certification itself is managed by qualified inspectors, understanding and applying these steps can help reduce risk and extend equipment life.

At Mobile Hydraulic Specialties, we supply hydraulic accumulators, offer servicing expertise, and provide technical support to help your systems run safely and efficiently.

Contact us today to learn about our accumulator solutions, servicing support, or to learn more about how our hydraulic expertise can assist your business.

Related Blog Article: A Guide to Hydraulic Accumulator Maintenance and Operation

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au