Uncover the synergy of planetary reduction gearboxes in hydraulic motors. Available at Mobile Hydraulics, redefine industrial processes. Call (03) 9798-6511.

Hydraulic motors are components utilised in major industrial tools and machines to ensure the movement of their components. They convert fluid energy into mechanical motion through the principles of fluid dynamics. Now, one component that can make hydraulic motors more efficient, more powerful, and more precise is a planetary reduction gearbox.

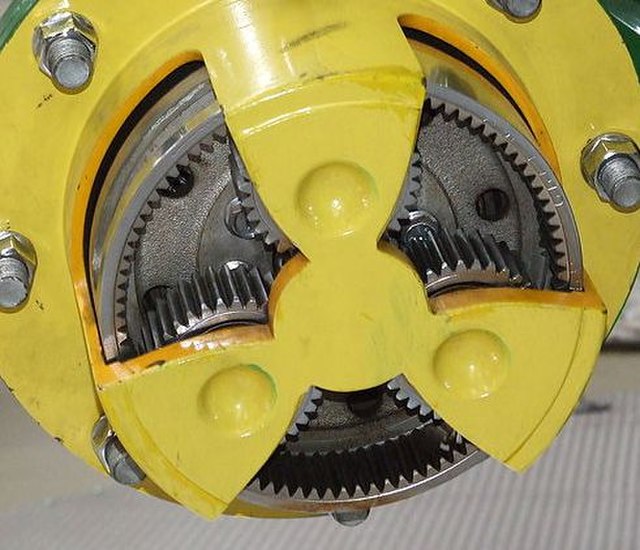

A planetary reduction gearbox is a type of gear system characterised by a central gear or a sun gear, surrounded by multiple smaller gears, known as planet gears, and an outer ring gear. This specific arrangement allows for compact design, increased torque output, and versatility in transmitting power.

The sun gear of this component drives the system, engaging with and driving the planet gears, which in turn rotate around the sun gear and mesh with the stationary ring gear. The interaction of these parts results in torque multiplication and speed reduction simultaneously.

When integrated with hydraulic systems, planetary reduction gearboxes can perform the following major roles.

• Enhanced Torque Multiplication: Planetary reduction gearboxes excel at torque multiplication. In hydraulic systems, the ability of planetary gears to distribute load across multiple contact points results in higher torque output from the hydraulic motor.

• Efficient Power Transmission: Planetary gearboxes ensure efficient power transmission from the hydraulic motor to the driven load. The distribution of load among multiple gears reduces frictional losses, maximising the overall efficiency of the system.

• Precision Control: Hydraulic systems often require precise speed and torque control. Planetary reduction gearboxes offer exceptional precision in controlling rotational speed, allowing for fine-tuning of hydraulic motor output to match the specific requirements of diverse industrial processes.

• Guaranteed Integration: The inherent compactness of planetary gear systems is particularly advantageous in hydraulic applications where space constraints are a concern. This design feature allows for the integration of powerful gear systems within limited spaces, optimising the overall footprint of hydraulic motors.

• Ensured Longevity: The robust construction of planetary gears, along with their ability to share the load, enhances the durability and reliability of hydraulic systems.

All major roles of planetary reduction gearboxes make them useful in a lot of machines across various industries. The construction industry, for instance, utilises these components for construction machinery, excavators, and bulldozers. The agricultural industry also integrates planetary reduction gearboxes into tractors, harvesters, and other agricultural equipment. Even conveyor systems, cranes, and other material handling equipment can utilise planetary reduction gearboxes. Ultimately, planetary reduction gearboxes can be installed in automotive manufacturing equipment.

As technology advances, the integration of planetary reduction gearboxes with hydraulic motors will continue to evolve. Innovations in materials, lubrication systems, and design optimisation can drive improvements in efficiency, reducing environmental impact, and expanding the range of applications.

Available at Mobile Hydraulics, planetary reduction gearboxes can significantly revolutionise hydraulic systems and contribute to the efficiency, precision, and reliability of industrial machinery. The synergy between these components represents a harmonious blend of mechanical engineering prowess, ensuring that the wheels of progress keep turning across various industries in Australia.

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au