Assess the performance of mobile hydraulics in harsh environments through mobile hydraulics testing by Mobile Hydraulic Specialties. Call us at (03) 9798-6511.

Mobile hydraulic systems are a critical component in various industries as they provide power and control for heavy equipment and machinery. They operate in diverse and challenging environments, ranging from construction sites to agricultural fields and mining operations. With such demanding conditions, ensuring the performance and reliability of mobile hydraulics and their connected systems is of utmost importance.

Hydraulic systems, after all, are subject to immense pressure, extreme temperatures, and abrasive contaminants, which can significantly impact their efficiency and lifespan. One of the primary ways to address these challenges is through mobile hydraulics testing.

The Significance of Mobile Hydraulics Testing

Mobile hydraulics testing assesses the functionality and performance of hydraulic components and systems under real-world conditions. It provides valuable insights into the capabilities of the system, identifies potential issues, and helps optimise hydraulic operations.

Through mobile hydraulics testing, the following benefits can be expected.

• Identified Performance Issues: Testing allows technicians to monitor hydraulic systems for any signs of performance degradation or inefficiencies. By simulating actual working conditions, testing can uncover problems that may not be evident during regular operations.

• Ensured Safety and Reliability: In harsh environments, safety is paramount. Mobile hydraulics testing detects potential failures or weaknesses in the system, allowing for proactive maintenance and minimising the risk of accidents or breakdowns.

• Improved Efficiency: Testing can help fine-tune hydraulic systems to achieve optimal efficiency, reducing fuel consumption and operational costs. By optimising the system’s performance, businesses can maximise productivity and minimise downtime.

• Extended Lifespan: Hydraulic components are often expensive to replace, making it essential to extend their lifespan. Regular testing and maintenance can help identify wear and tear early, preventing major failures and increasing the longevity of equipment.

Primary Mobile Hydraulics Testing Methods

A wide range of methods can be employed to check and evaluate the performance of mobile hydraulic systems. These methods include the following:

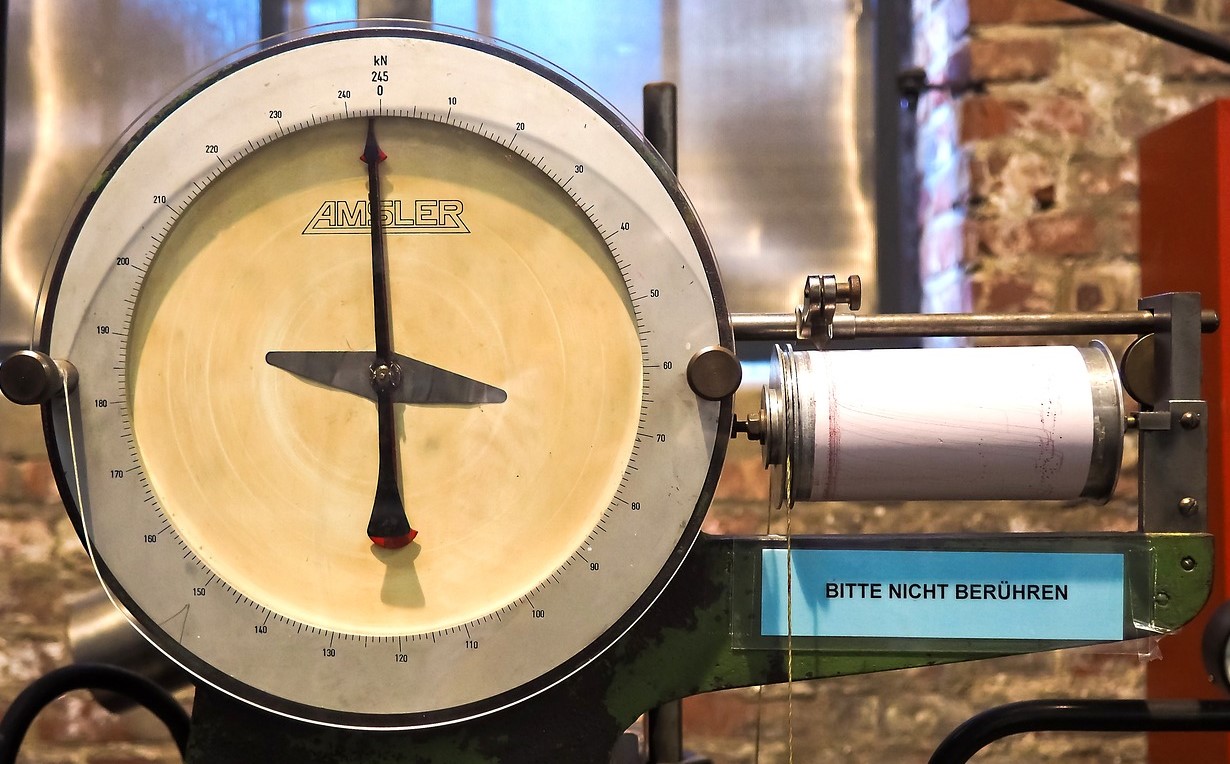

• Pressure Testing: Pressure testing subjects the hydraulic system to different pressure levels to assess how it responds under varying conditions.

• Load Testing: Load testing involves applying external forces to the hydraulic system to evaluate its strength and stability when handling heavy loads.

• Temperature Testing: Extreme temperatures can affect hydraulic fluid properties and component performance. Temperature testing assesses the ability of the system to operate effectively in different temperature ranges.

• Contamination Testing: Mobile hydraulic systems often encounter contaminants like dirt, debris, and moisture. Contamination testing evaluates how well the system handles these elements and identifies potential points of failure.

• Durability Testing: Durability testing subjects the hydraulic system to repetitive stress and shock to evaluate its resistance to wear and fatigue.

• Environmental Testing: To ensure performance in harsh environments, environmental testing assesses how well the hydraulic system operates in extreme weather conditions, such as high humidity, saltwater exposure, or freezing temperatures.

Mobile hydraulics testing plays a vital role in maintaining the efficiency and reliability of hydraulic systems operating in challenging environments. By identifying performance issues early and optimising system operation, businesses can improve productivity, reduce downtime, and ensure the safety of personnel and equipment. Regular testing is crucial for extending equipment lifespan and minimising operational costs, making it an indispensable practice for any industry that relies on hydraulic systems in harsh conditions.

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au