Maintain hydraulic efficiency with Mobile Hydraulic Specialties’ mobile hydraulic service and detailed inspection for fleet equipment in Melbourne.

Truck-mounted equipment requires stringent maintenance to ensure operational safety and maximum uptime. Deploying a specialised mobile hydraulic service mitigates unnecessary downtime associated with transporting heavy plant to a static workshop. Fleet managers must implement a detailed, proactive inspection regime to manage complex risks effectively and preserve asset reliability.

Hydraulic failure leads to catastrophic machine malfunction and presents severe safety risks for operators and surrounding personnel. Premature component wear reduces machine efficiency, increasing fuel consumption and operational costs significantly over the asset’s life. Routine technical assessments accurately identify minor faults before they escalate into major, expensive repairs.

High-pressure fluid leaks contaminate the environment and often result in immediate compliance breaches under strict Australian environmental regulations. Prolonged exposure to extreme operating conditions stresses hoses, seals, and fittings beyond standard tolerances, drastically reducing their lifespan. Systematic, documented checks extend the asset’s overall service life, protecting the considerable capital investment made in heavy plant.

A professional mobile hydraulic service prioritises system integrity and operational functionality during every inspection cycle. Maintaining hydraulic health is paramount for meeting Australian safety standards and achieving high operational throughput across the fleet.

Fluid integrity and level checks:

• Fluid Level: Verify the reservoir fluid level adheres strictly to manufacturer specifications under designated operating conditions.

• Fluid Condition: Assess the hydraulic fluid for discolouration, contamination, or evidence of water ingress, which degrades performance.

• Filter Status: Inspect all spin-on and suction filters for clogging or any physical damage to the media that could compromise filtration effectiveness.

• Temperature Gauge: Monitor the maximum operating temperature recorded by the gauge or sensor to identify potential heat dissipation issues.

• Air Bleeding: Check for and purge any trapped air or gas (aeration) within the system lines or actuators that may cause spongy operation.

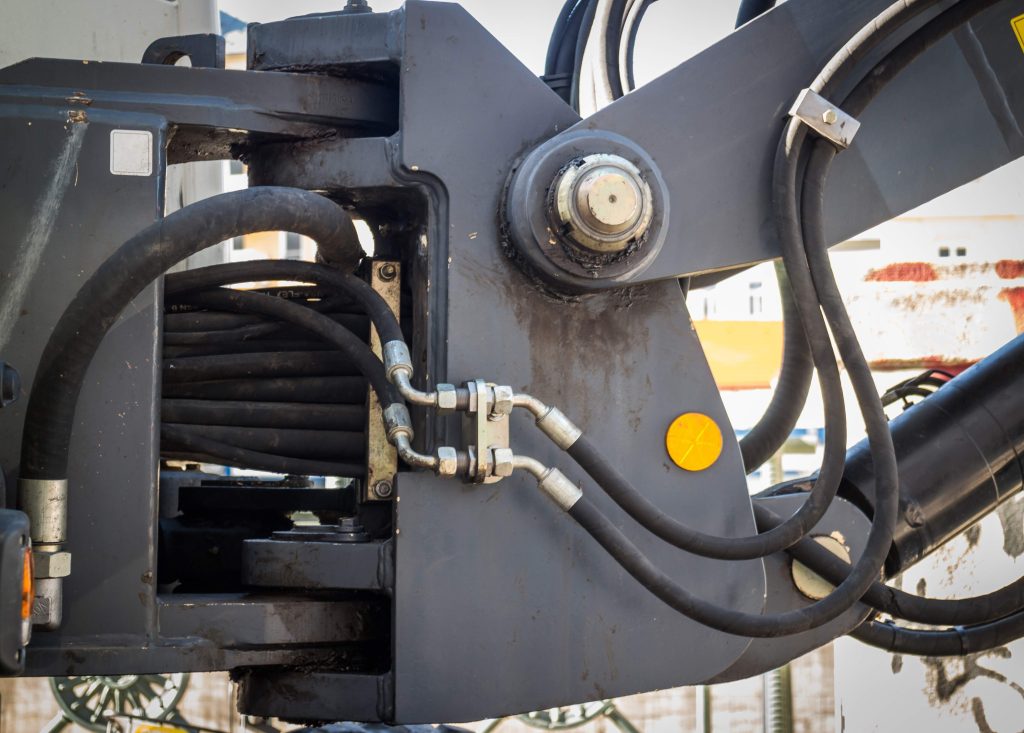

The structural security of hydraulic components prevents unplanned movement and critical system failure during lifting or material handling operations. Detailed inspections focus on the physical state of components that are subject to constant movement and high-force stresses.

Component examination points:

• Hose Assemblies: Examine all flexible hoses for signs of abrasion, kinking, and bulging, and confirm correct routing clearance to prevent premature wear.

• Cylinder Condition: Inspect cylinder barrels and rods for scoring, excessive leakage, and verify proper seal retention at the gland nuts and piston ends.

• Mounting Points: Verify the fasteners and mounting brackets for the hydraulic pump and control valves are torqued correctly and entirely free of corrosive degradation.

• Valve Functionality: Test all pressure control and relief valves to confirm their correct pressure setting and ensure smooth, responsive operational cycling.

• Ancillary Systems: The comprehensive remit of a professional mobile hydraulic solution ensures safety systems like load-limiting devices are properly calibrated and function accurately as designed.

For further insights on the regular inspection and maintenance of plant are critical requirements under Australian safety legislation, see Victoria’s Occupational Health and Safety Act 2004 (WorkSafe Victoria).

Proactive maintenance maximises asset utilisation across the work schedule and eliminates unexpected, costly disruptions.

Mobile Hydraulics Specialties provides specialised field support built around precise diagnostics and responsive mobile hydraulic service delivery. Our technicians maintain system efficiency and help fleet managers protect long-term equipment performance.

Contact us for comprehensive service and equipment assessment.

Related Blog Article: Comprehensive Mobile Hydraulic Solutions for Industrial Machinery

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au