Safeguard hydraulic equipment with Mobile Hydraulics’ industrial filtration services, ensuring optimal function and long-term system reliability.

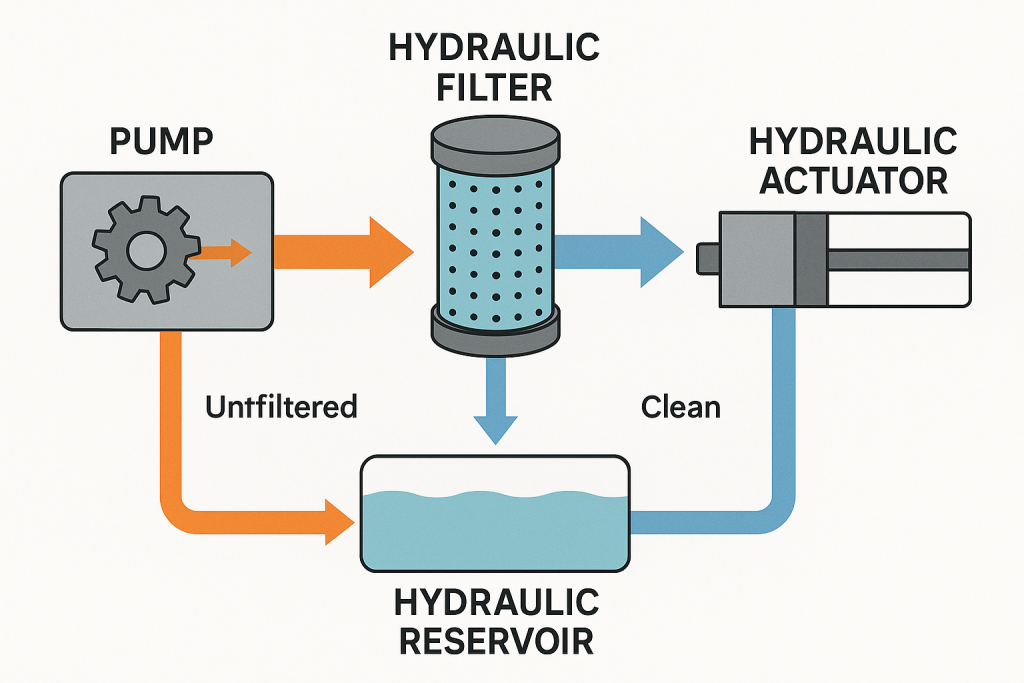

Industrial filtration services optimise hydraulic systems by ensuring contaminants are removed, facilitating smooth operations and reducing wear on components. Clean hydraulic fluids enhance system reliability, minimise energy consumption, and extend equipment lifespan, making filtration indispensable for industries reliant on precision machinery.

Efficient filtration prevents blockages in hydraulic circuits, maintaining consistent pressure levels and reducing the risk of system failures. This contributes to enhanced productivity and lowers operational costs through reduced downtime and maintenance requirements.

Advanced filtration technologies support high-pressure systems by maintaining fluid purity, enabling accurate and reliable performance under demanding conditions. These solutions are integral to ensuring operational efficiency across diverse industrial applications.

Contaminants such as particles, water ingress, and degraded oil compromise hydraulic systems, leading to increased wear and potential failure. Industrial filtration services mitigate these risks by removing impurities before they impact system functionality.

Adding fluid level sensors and switches to hydraulic reservoirs can shut down systems or trigger alarms during hose failures or oil loss, preventing costly damage. Monitoring oil temperatures in reservoirs or key components ensures optimal fluid conditions, improving component longevity and reducing downtime.

Selecting appropriate filtration solutions requires evaluating specific system requirements to ensure compatibility and efficiency. Factors such as operating pressure, flow rate capacity, and environmental conditions must be considered for optimal performance.

• Flow Rate Compatibility: Filters should match the system’s flow rate capacity to prevent pressure drops or inefficiencies during operation.

• Robust Design: Systems operating in harsh environments benefit from filters engineered to withstand extreme conditions without compromising functionality.

• Dirt-Holding Capacity: Filters with high dirt-holding capacity reduce maintenance frequency while maintaining fluid cleanliness over extended periods.

• Integration Options: Compatibility with existing components ensures seamless integration without affecting system performance or reliability.

• Indicator Features: Advanced indicators enable the timely servicing of filters, preventing unexpected downtime caused by contamination buildup.

• Customisation Potential: Tailored filtration setups cater to unique industrial applications, providing solutions specific to operational needs.

• Secondary Filtration Measures: Incorporating secondary filters enhances overall protection by addressing contaminants missed during primary filtration processes.

Mobile Hydraulics offers industrial filtration services designed to keep hydraulic systems clean and efficient, ensuring optimal performance for diverse applications. Our comprehensive range of products and advanced indicators for proactive servicing delivers measurable benefits for clients across industries.

Seek custom solutions at Mobile Hydraulics for any specific filtration issues needing resolution in hydraulic punching processes.

Learn advanced information about the topic with this content: How Next-Gen Hydraulic Filters Keep Your Operations Running Smoothly

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au