Uncover essential tips on selecting the right fluid level sensor for your hydraulic system. Let Mobile Hydraulic Specialties improve your hydraulic system.

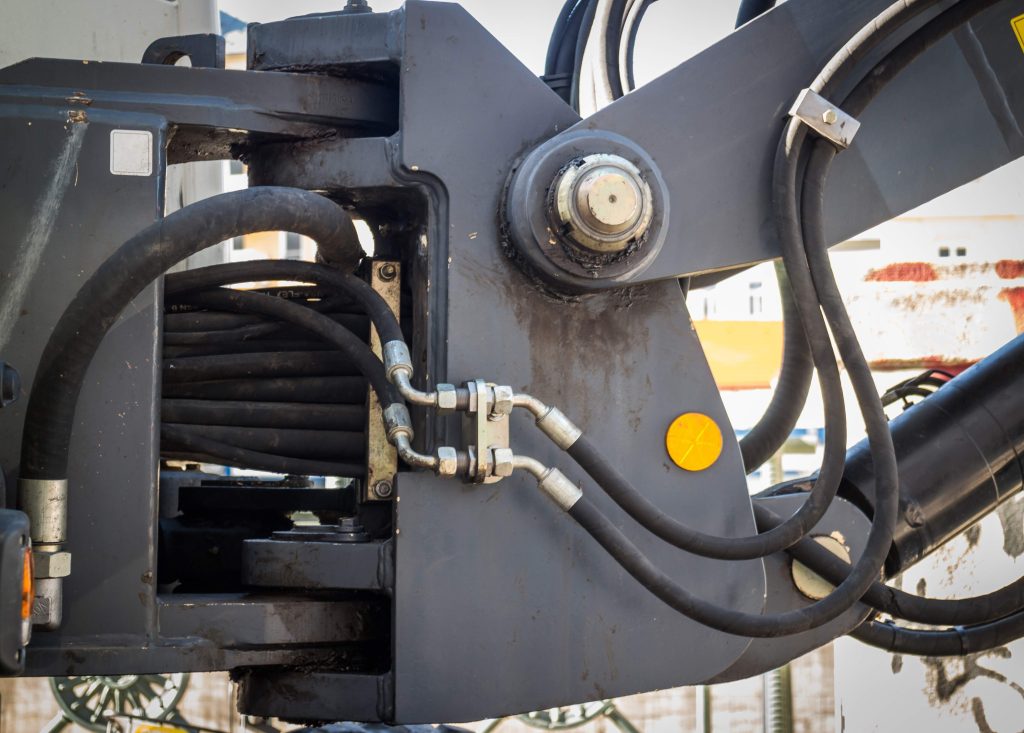

Choosing the right fluid level sensor for your hydraulic system is essential for maintaining optimal performance and ensuring safety. With various sensor types and technologies available, understanding their features and compatibility is essential for effective application.

Make an informed decision that enhances efficiency and reliability in your operations through the following tips. Whether you’re dealing with hydraulic fluids in harsh environments or integrating sensors with existing systems, these tips will ensure you select the best fluid level sensor for your needs.

Understand Your Requirements

The first thing you should do in selecting a fluid level sensor is to assess the specific needs of your hydraulic system. Consider the type of fluid being used—whether it is oil, water, or another hydraulic fluid—as different sensors are designed to work with specific media. Moreover, determine the operating temperature and pressure ranges, as these parameters will affect sensor compatibility.

Match Your Needs

Fluid level sensors come in various types, each with its advantages and limitations. Some of the most common types of fluid sensors include:

• Ultrasonic Sensors: These sensors use sound waves to measure fluid levels without physical contact, making them suitable for hazardous environments.

• Capacitance Sensors: These sensors detect changes in capacitance caused by fluid level variations. They are versatile and can be used for various fluids.

• Float Sensors: Simple and reliable, float sensors use a buoyant device that rises and falls with fluid levels. They are suitable for most hydraulic applications but may require regular upkeep.

• Pressure Sensors: These sensors measure fluid pressure at the bottom of the tank to determine the fluid level. They are reliable for high-pressure systems but can be complex to install.

Understanding the pros and cons of each sensor type will help you make an informed choice that aligns with your application.

Consider Installation Environment

The installation environment plays a significant role in sensor selection. If your hydraulic system operates in a harsh environment, then you should choose a sensor designed to withstand those conditions. You must then look for features like robust housing materials, IP ratings (Ingress Protection), and temperature resistance to ensure durability and reliability.

Ensure System Compatibility

Consider how the fluid level sensor will integrate with your existing hydraulic system. You must look for compatibility with control systems, alarms, and monitoring equipment. Many modern sensors offer digital outputs and can communicate with automation systems, which allows for real-time monitoring and control. You must then ensure that the chosen sensor can easily connect to your existing hardware to avoid additional costs and complexities.

Verify Calibration and Upkeep Needs

Different sensors have varying calibration and maintenance requirements. Some sensors may need regular calibration to ensure accuracy, while others may be self-calibrating. You must assess the maintenance resources available in your operation and choose a sensor that aligns with your capacity for ongoing maintenance. Sensors that require less frequent maintenance can reduce your overall operational downtime and costs.

Choosing the right fluid level sensor for your hydraulic system involves careful consideration of your application needs, environmental conditions, and integration capabilities. If you need help in selecting and sourcing fluid level sensors, contact us now at Mobile Hydraulic Specialties.

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au