Denison’s single, double, and triple vane pumps configurations operate efficiently in various applications. Learn how they meet diverse industrial needs.

Vane pumps are integral to many hydraulic systems, providing reliable performance and efficiency across various applications. Denison, a renowned name in hydraulic technology, offers a range of vane pumps, including single, double, and triple configurations. Each configuration has unique characteristics and applications, making them suitable for different operational needs.

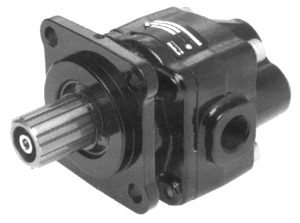

Denison’s single vane pumps are the most straightforward in their design. They consist of a single set of vanes that rotate within a cam ring, creating a series of expanding and contracting cavities. This design allows for consistent fluid delivery and is ideal for applications requiring steady, moderate flow rates.

Denison’s single vane pumps offer a range of benefits that make them a reliable choice for various hydraulic applications. Here’s a closer look at their key performance features:

• Efficiency: Single-vane pumps are renowned for their high volumetric efficiency, minimising fluid leakage and ensuring reliable, consistent performance. This efficiency makes them ideal for applications where precision and reliability are crucial.

• Simplicity: Their straightforward design translates to lower maintenance needs and ease of operation, reducing the overall cost of ownership and upkeep. This simplicity is a key advantage for users seeking hassle-free performance.

• Applications: These pumps are well-suited for low to medium-pressure applications, making them perfect for small hydraulic systems in machinery and automotive components. Their versatility allows for effective use in various demanding environments.

The double vane pump configuration features two sets of vanes operating in tandem. This setup effectively doubles the capacity and flow rate compared to single vane pumps, making them a versatile choice for applications requiring higher performance.

Denison’s double vane pumps enhance hydraulic system performance with their advanced design. Here’s how their performance features stand out:

• Increased Flow: Double-vane pumps utilise two sets of vanes to achieve higher flow rates and pressure capabilities than single-vane models. This enhancement enables them to handle more demanding hydraulic tasks with ease.

• Versatility: These pumps are highly versatile, making them ideal for systems that require higher fluid volumes and stable pressure. Their adaptability allows them to perform efficiently in a variety of applications.

• Applications: Double-vane pumps are commonly used in medium to high-pressure systems, such as those found in industrial machinery, agricultural equipment, and hydraulic presses.

Triple vane pumps take the concept of vane technology to the next level with three sets of vanes. This configuration is designed for high-capacity and high-pressure applications, offering superior performance and efficiency.

With three sets of vanes working simultaneously, these pumps deliver smooth, continuous flow with minimal pulsation. This is ideal for large hydraulic systems and high-demand applications, such as construction machinery, large industrial equipment, and mobile hydraulic systems.

Selecting the appropriate vane pump configuration depends on several factors, including the required flow rate, pressure, and the specific application needs. Single vane pumps are ideal for less demanding systems, while double and triple vane pumps are better suited for higher capacity and pressure requirements.

Denison’s vane pumps, in single, double, or triple configurations, provide reliable and efficient performance for various applications. Understanding each configuration’s strengths helps you optimise your hydraulic system’s performance and durability. Contact Mobile Hydraulics for your vane pump needs.

Factory 89, 38-40 Popes Road

Keysborough, Victoria, 3173

Phone: (03) 9798-6511

Optimized by NetwizardSEO.com.au